3D Printing in Madrid

Discover the Best 3D Printing and Rapid Prototyping Solutions in Madrid

We have been 3D printing since 2012 and the early days of the RepRap movement. During this time we have used several different types of 3D printer, from our first RepRap Mendel kit and home brews, to our current Prusa Bedslingers and CoreXYs. During this time we have accumulated thousands of hours of experience with 3D printing technology and materials.

TheLink3D, the 3D printing arm of New Skin Design, dedicated to all things 3D Printed, offers a wide range of solutions and 3D printing services in Madrid, for all your project needs.

For more 3D printing news, follow us on twitter: @thelink3ddotcom.

The 3D Printing Process

Over the last 10 years or so, 3D Printing technology has opened up rapid prototyping to the masses. What was once a process reserved for large corporations due to its restrictive costs is now available to everyone.

We specialize in Fused Filament Fabrication (FFF/FDM) and with our equipment and experienced team, we can bring your ideas to life in days.

Simply speaking, the 3D printing process begins with a 3D or CAD model of the object to be printed. Slicing software is then used to slice the model into thin horizontal layers and this information is outputted in a file format that the 3D printer can read. When a print is started, the head of the 3D printer heats and extrudes plastic filament to form a thin layer of the object’s cross section. This process is repeated by printing layer upon layer until the object is completed.

The advantages of 3D Printing are low costs and quick turnaround times. Prototypes can be made in days and without the need for special tooling. A 3D printed prototype allows for the evaluation of its design. Form, fit and function can be reproduced allowing any design problems to be identified early and resolved before larger scale production.

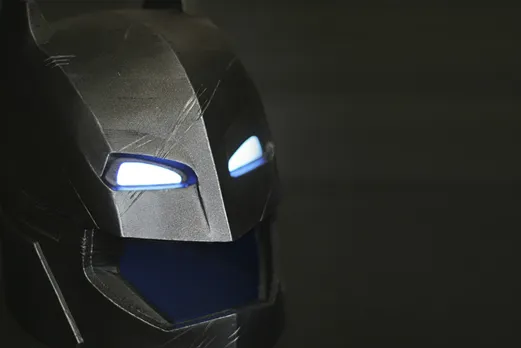

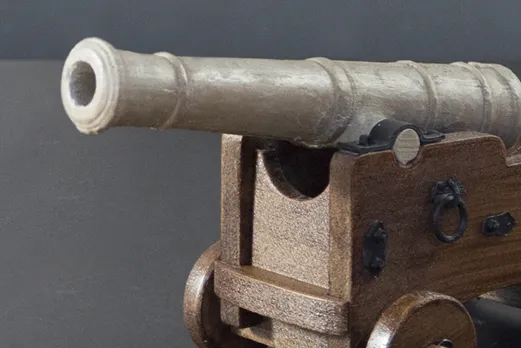

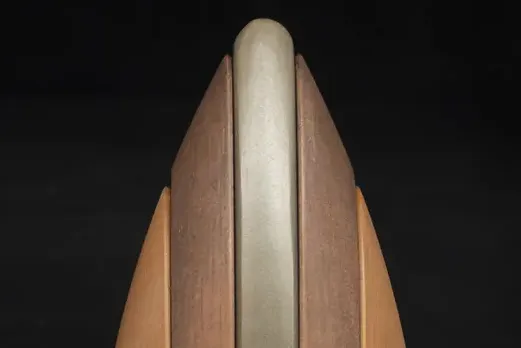

Our 3D Printing Work

3D Printing Materials

We currently offer 3D printing solutions in various materials including PLA, PETG, ABS, Nylon, Flex and Composites, among others. Each material has its own advantages and disadvantages, and we can advise you on which one is best suited for your project.

Below we have outlined the main advantages and disadvantages of the most popular 3D printable materials.

PLA

- The most commonly used filament

- Easy to print

- Gives good level of detail, ideal for prototypes and architectural models

- Strong

- Brittle

ABS

- Strong, durable (used for Lego bricks!)

- Easy to post process parts (joining and smoothing with acetone)

- Ideal for prototypes requiring mechanical integrity

- Difficult to print large objects due to warping

PETG

- Almost as easy to print as PLA with better mechanical properties

- Ideal for prototypes or final use parts

- Stringing may occur, but can be removed with a heat gun

Flex

- Ideal for applications that require flexibility

- Hard to print

- Needs to be printed slowly

Nylon

- Very tough

- Good for small, practical final use parts

- Hard to print

- Poor level of detail, not suitable for very detailed parts

Composites

- Usually consisting of PLA combined with a second material

- Easy to print

- Impressive looking finishes can be achieved

- Requires hardened nozzle to print due to abrasive nature

The Truth about 3D Printing

There are many misconceptions about 3D printing, and although it has been a game changer in the rapid prototyping and product design industries, it should be noted that it is rarely just a "click and print" process – there is more going on behind the scenes.

You need a 3D file of the object you want to print. You can provide the file or we can prepare it for you. The 3D model then needs to be analysed to determine the optimal way to print it, for example are there overhangs that need supports?, is a brim needed to improve print bed adhesion?, in what orientation should the object be printed? etc. Print orientation can affect an object’s strength, print time and print quality. The 3D printing process is rarely 100% perfect and failed prints are not uncommom. An object may need to be printed multiple times to get the best result possible.

We go the extra mile to ensure that your 3D print is of the highest quality.

To get started, simply send us your prepared 3D model file for printing, or have us prepare your design using our 3D and Product Design service. We accept 3D files in .STL, .STEP and .OBJ formats via email or wetransfer.com for larger files (>20 MB).

Request Your Free Quote Today

Tell us about your project and which Design Services you require. We will get back to you with more information and a quote.

Get In Touch